Sfic 7 and 6 Pin/ Brass /Core /Ring Keys/ The Cylinder for Use in Electronic Locks /Interchangeable/Security Doors

Basic Info.

| Lock Body Structure | Single Bolt |

| Lock Body Type | Single |

| Key Type | Triplex Row Anti Dialing Key |

| Key Functions | Lock Core, Lock Body |

| Key Level | C |

| Surface Treatment | Electroplating |

| Anti-Theft Lock Core | The Standard C Grade |

| Transport Package | Pre-Packaging Export Packing |

| Specification | 2050*860, 2050*960, 1970*960, 1970*860 |

| Trademark | CNC LATHING junying |

| Origin | Dongguan, Guangdong, China |

| HS Code | 8530800000 |

| Production Capacity | 100000PCS/Year |

Product Description

Product Details

Specifications of Junying CNC Machining Lock Parts

- Lock Product Types: interchangeable core, rim cylinder, key-in-knob cylinder, euro profile, oval profile, SFIC cores, IC core, custom SFIC locks, lock cylinder, mortise cylinder, cam lock housings, cam lock nuts, cam latches, cam lock washers, cam lock cam, door lock parts, lock core, push lock housing, push lock spring, blank key, etc.

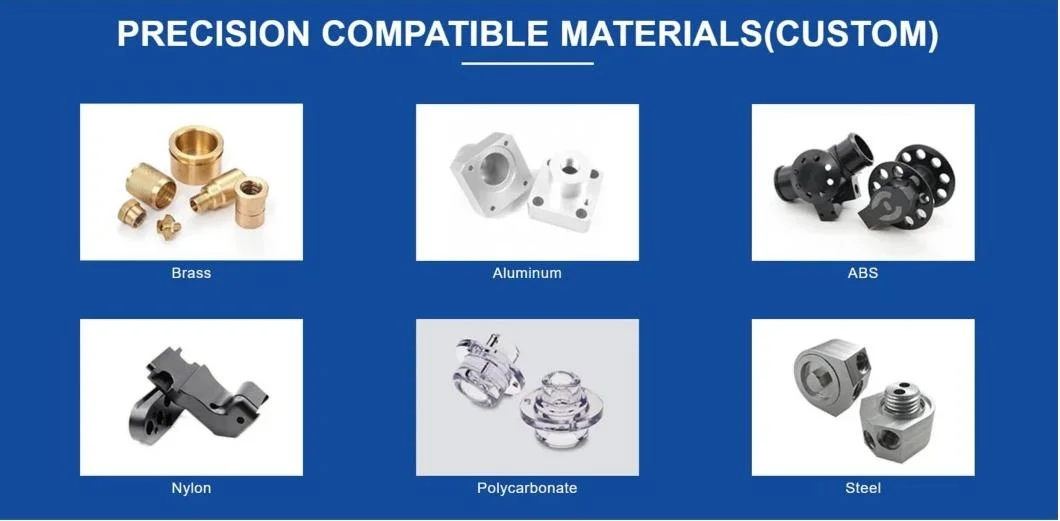

- Materials for CNC Lock Parts: copper, stainless steel, zinc alloy, aluminum alloy, etc.

- Lock Cylinder Production Process: CNC machining, CNC milling, CNC turning, CNC drilling, etc.

- Lock Core and Accessories Applications: cam lock, door lock, push lock, SFIC lock, padlock, IC core lock, security lock, and other types of locks in various industries

- Lock Parts Surface Finishes: 190(Matte Black), US3(Bright Brass), US4(Satin Brass), US15(Satin Nickel Plated), US26(Bright Chrome), US26D(Satin Chrome), et

- Types of Lock Keyways: A, B, H, J, K, L, M, N, S, WA, WB, WC, BA, D, DD, E, F, G, P, Q, R, TA, TB, TC, etc.

Advantages of Junying Lock Parts Machining

- Quality assurance: a series of advanced facilities such as abrasion tester, salt spray test, optical emission spectrometer, with seasoned operators are ready to carry out visual quality standards for our finishing services to avoid the different appearances of the different batch, and more measuring equipment used to confirm the product dimensions. As shown in the video, Junying will carry out the strict aging tests on our IC core and door lock parts, to ensure the durability and quality of our machining parts.

- Cost-effective production: As an ISO certificated lock core manufacturer, we carry out strict control of product quality and production process, as well as PMI (positive material identification) for incoming materials, thus extend the service life of lock product, maintain high efficiency of mass production, reduce the errors and cost, provide the utmost security at the same time.

- Extensive applications: our lock core parts are widely used in electronics, defense, communications, medical, marine and more industries, there is a large amount of CNC lock products have been exported to the United States and majority of European countries.

- Customer service: if you are looking for top quality commercial lock cylinder or home lock parts for your project, welcome to contact us through our email or just leave an message on our page, our staff will give you the reply and send you free quote fast according to your drawing or requirements. "Add to Cart" and "Payment" function will be available in the near future, in order to make customers buy standard lock parts conveniently.

Our Advantages

Applications

Applications of Junying CNC Machining Services

CNC machining parts are all around you, they may be important components of your car and also can perform vital functions in your electrical equipment. Junying is an accomplished CNC supplier that engaged in a broad range of CNC machining applications.

| Manufacturing Process | Milling, Turning, Grinding, Fast/Midium/Slow Wire EDM, Welding, Metal Plate, Etc. |

| Material | Brass,SN, PB, SB, BLK, and so on |

| Surface Treatment | Galvanized (zinc-plated, nickel-plated, chrome-plated, silver-plated),powder coating/oil painting, polishing (mirror polishing, electrolytic polishing),brushing, sand blasting, anodizing etc |

| Tolerance | +/-0.01mm or special requirements |

| Package | PE Bag, Paper carton box, plywood case/pallet/crate |

| Application | Making master locking system |

| Quality Control | SFIC cylinder |

| Drawing File Format | Solidworks, Pro/E, Auto CAD, PDF |

| Features |

|

| Inspection | IQC, PQC, FQC, OQA |

| Delivery time | 10-15days |

| Quality Insurance | One Year |

Company Profile

Junying is a leading China lock cylinder manufacturer and CNC machining services company of precision machined lock parts and accessories for the mechanical security industry, we have been dedicated to the lock cylinder machining and production in standard and custom specifications for more than 10 years. Our CNC machining center, sophisticated manufacturing facilities and advanced inspection equipment, as well as professional engineers and skilled machinists are assisting our door locks cylinder manufacturing to meet the customers requirements, capabilities including CNC milling, turning, drilling, and finishing. We provide a complete selection of lock components including SFIC core, IC core, lock cylinder, mortise cylinders, cam lock housings, cam lock nuts, cam lock washers, door lock parts, push lock housing, push lock spring, blank key, key cylinder, key core, etc. Strict quality control system and a series of inspection procedure enable us to deliver each product with quality and performance conforms to the clients' needs.

Production Process

CNC Machining for Lock and Key Industry

With the development of security industry in modern society, Computer Numerical Control machining has become the main manufacturing solution of a variety range of locks and keys. To ensure the safety and security of people, the quality of each part on the lock is important. As the essential device on security doors, home door, market entrance and other places, the demand for locks and lock parts is huge every year. CNC manufacturing is one of the most efficient and cost-effective production method for large-batch engineering parts in same size. Based on the decades of experiences on the development and machining of lock cylinder, lock core, keys, and different lock parts, Junying is familiar the unique characteristics of lock accessories and things to notice during the fabrication process, and capable to produce OEM lock cylinder parts with various customized designs.

Hot Sale Junying CNC Machining Lock Parts & Accessories List

* Suitable for 6 or 7 pins SFIC.* 1 nickel silver control key and 2 nickel silver operating keys.* Able to make master key system up to 5 levels (GGGMK). * Construction key function (Optional).* Contact us for more details.

Packaging Details

Each product packed with plastic preservative, EPE, foam plastic bag, Carton outside, wood case or iron case or as per the customer's special requirement.

Logistics

We prefer DHL or TNT express or other air freight between 1kg-100kg.

we prefer sea freight more than 100kg or more than 1CBM

As per customized specifications.

Payment

We accept payment by T/T, PayPal.

FAQ

Q: What do I need for offering a quote?

A: Please offer us 2D or 3D drawings (with material, dimension, tolerance, surface treatment and another technical requirement, etc.), quantity, application, or samples. Then we will quote the best price within 24h.

Q: What is your MOQ?

A: MOQ depends on our client's needs, besides, we welcome trial orders before mass production.

Q: What is the production cycle?

A: It varies a lot depending on product dimension, technical requirements, and quantity. We always try to meet customers' requirements by adjusting our workshop schedule.

Q: What kind of payment terms do you accept?

A.: T/T, PayPal.

Q: Is it possible to know how is my product going on without visiting your company?

A: We will offer a detailed production schedule and send weekly reports with digital pictures and videos which show the machining progress.

Q: If you make poor quality goods, will you refund our fund?

A: We make products according to drawings or samples strictly until they reach your 100% satisfaction. And actually we won't take a chance to do poor quality products. We are proud of keeping the spirit of good quality.

For more questions, please send an inquiry or e-mail or call us! Thanks!